SMP1240ND Radius Forming Pads

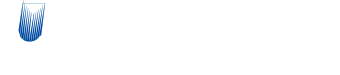

This new patented design SMART PAD® is an improved version. With an interlocking wear pad, this tooling system can be used to form virtually any large radius, in any gauge or type of metal.

- With a bottom die stack height of about 5.5", this urethane forming/pressure pad is designed with a molded relief area below the radius forming pad that is sized proportional to the radius punch and is shaped to offer progressively increasing forming pressure, as the punch descends into the forming pad.

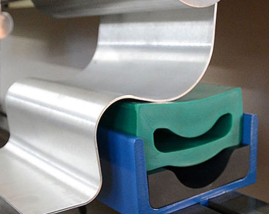

- Forming pads are available in hardness: 70A (Blue), 80A (Green), 90A (Red or Orange) or 95A (Amber or Tan). Selection of hardness is dependent on the gauge of metal being formed, and the tonnage available on the machine.

- The two molded belt-drive shaped holes are designed for reducing the tonnage required for forming and to exert progressively increasing forming pressure.

- Interlocking Wear pad is usually one durometer grade harder than the forming pad.

The part shown above is by using the same urethane forming pad (SMP1240ND) as the bottom die and just by changing the punch, 6 different radii are formed. Up to 1/4" thick S.S. can be formed to virtually any radius.

Pressure Pads

Pressure pads (or wear pads) are a crucial functional part of this design. The Pressure Pad is inter-locking to the forming pad with the molded keyway which locks into a matching slot in the backside of the forming pad anchoring between the steel retainer and the forming pad, as the punch pushes down into the forming pad. The pressure pad hardness and thickness can be varied to offer higher forming pressures and provide better cut-resistance while forming heavier gauge metal or for sheet metal with sharp edges that might cut into the forming pad. Pressure pads are at least one grade harder than forming Pads.

For applications where the tonnage available is lower, forming pads are made with molded relief holes shaped like a belt drive.

ORDERING INFORMATION

STEEL CHANNEL PART NUMBER: CR20120

(add length in inches to PAD & STEEL RETAINER part numbers)

Other SMART PAD®

Hundreds of this original design SMART PAD® are in use all over the world for more than 3 decades.

Learn More

The original design SMART PAD® for smaller radius forming. This pad is ideal for radii ranging from 1”-3”.

Learn More

This patented new design SMART PAD® system for heavy duty applications. Pads can form as thick as ½” Mild Steel to any radius.

Learn More

This patented new design SMART PAD® system has a unique molded steel rod and interlocking wear pad. Can be used for up to 3/8” stainless steel.

Learn More

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.