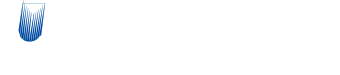

SMP1240 Radius Forming Pads

This original design Radius Bending system has been a very successful tool used by hundreds of Fabricating shops, for more than 30 years.

- Designed for bending up to 1/4" thick Stainless Steel.

- Pads are molded in 48" lengths, and for longer bends, SMP1240 urethane forming pads can be butted together end to end to make any length.

- We have produced dies 65 ft. long to produce tapered light poles.

- Wear pads are used to reduce damage from sharp sheet metal blanks cutting into the forming pad.

- CAUTION: The punch length should be equal to or longer than the pad length. If the length of the punch is shorter than the pad length, ends of punch will dig into the pad and damage the pads. It is better to cut the pad to be the same length as the punch or shorter.

Watch the Process

Imagine, forming a mar-free, radius of any size, any gauge of metal* using the same bottom die...you can stop imagining, it is now possible only with SMART PAD® SMP1240 & SMP620N! See how the SMART PAD® large radius tooling from Polyurethane Products can make your production faster and easier!

SMP 1240 Tooling System Success Stories

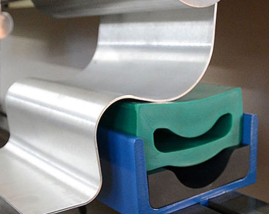

U-Troughs, 1/4" Thick Stainless Steel, 12’ Long Formed in 3 Hits, in Various Radii

One of our customers designs and builds material handling systems for the Municipal Waste Water market. Their conveyors use a variety of sizes of Stainless Steel U-troughs to house the screw or auger.

The old process to make these troughs was to use a CNC Press Brake to make about 40 hits at about 5 degrees each to create the 180-degree U-bend.

Major issues encountered in this process were:

- Stainless steel springs back differently from sheet to sheet and within a sheet to produce a distorted trough. The trough had to be re-hit & manipulated to bring it to the desired shape. The process was operator de-pendent for quality and productivity.

- They contacted Polyurethane Products Corp. for a solution to their manufacturing bottleneck. They described their needs and objectives and we had a solution. They provided test material and we developed several radius punches to be used with the same Urethane bottom Die.

The new process uses a variety of steel radius punches pressing into a Universal Polyurethane bottom die, called the SMARTPAD® system. - The small size troughs now require only 3 hits to accomplish what took 37 hits before.

Our Customer's Feedback

“Productivity increased and the quality is much better…

The troughs are created in one quarter the time and the troughs are perfect, with a smooth rolled appearance, without any chatter marks."

With the unique production capability of making the special steel radius punches and the unique SMARTPAD® system, and testing them to prove the functionality, the single-source responsibility by Polyurethane Products Corp., has improved productivity and quality.

Long Term Success in Manufacturing Bulk Solid Handling & Processing...

One of the leading manufacturing companies in the world involved in manufacturing screw conveyors and feeders has been using our SMART PAD® System and custom made steel punches to make perfect shaped U-troughs in a variety of gauges (16 Ga.-7 Ga.) in stainless steel as well as mild steel. We have made systems to bend 1/4” thick stainless steel for other customers.

This 12 ft. long set-up uses 3 pads SMP1240, 4 ft. long, butted end to end to produce any radius, just by changing the punch and using the same pad as a universal bottom die.

Quality is superior and productivity has improved many-fold because the number of hits to form the part is reduced from 40 to 3.

This customer replaces the pads about once a year with regular daily production.

We have many companies in the agricultural grain handling equipment manufacturing business that use our SMART PAD® system for making a variety of U-troughs for screw conveyors.

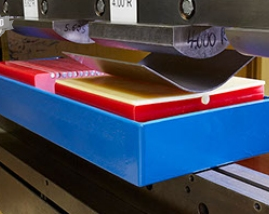

Architectural Column Covers Formed with SMART PAD® System

These Column covers made of 1/4” thick pre-painted Aluminum sheets for a 48” diameter Architectural Column cover project was the first major successful application of the SMART PAD® system, more than 30 years ago.

- 14 ft. long steel Radius Punch was used with an SMP1240 bot-tom Die and a Steel channel Retainer CR1240 to produce Mar-Free and consistent panels for the production of many panels required for the project. Quality was superb.

- This is another 48” Diameter Column Cover project for which we supplied the complete Tooling package to bend 10 GA. Polished Aluminum.

- The finished column covers in the background have a white plastic protective cover. To show the Mar-Free capability of the Urethane Tooling, we peeled off the plastic cover and formed the polished Aluminum sheet to a perfect radius bend. There are no lines or any kind of marks between the bump forming hits.

- 14Ft. Long Steel Radius Punch and the SMP1240 SMART PAD® system were manufactured at the same location and tested on this 400 Ton Press Brake which we use for development and try-out purposes.

Other SMART PAD®

The original design SMART PAD® for smaller radius forming. This pad is ideal for radii ranging from 1”-3”.

Learn More

This patented new design SMART PAD® system is an improved design with interlocking forming pad and wear pad, offering many advantages.

Learn More

This patented new design SMART PAD® system for heavy duty applications. Pads can form as thick as ½” Mild Steel to any radius.

Learn More

This patented new design SMART PAD® system has a unique molded steel rod and interlocking wear pad. Can be used for up to 3/8” stainless steel.

Learn More

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.