Polyurethane Metal Forming Pads

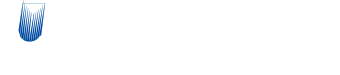

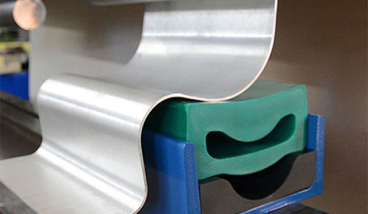

The patented SMART PAD® tooling system are Urethane pads for bending and forming, designed to create large radius bends in any gauge thickness and type of sheet metal ( up to 3/8” thick stainless steel). With press brake metal forming, virtually any radius can be formed just by changing the punch. Up to 8” surface arc width can be formed in one hit, enabling the possibility of turning a 38 hit bump forming process into just 3, with better quality and consistency.

SMARTPAD® Models

Hundreds of this original design SMART PAD® are in use all over the world for more than 3 decades.

Learn More

The original design SMART PAD® for smaller radius forming. This pad is ideal for radii ranging from 1”-3”.

Learn More

This patented new design SMART PAD® system is an improved design with interlocking forming pad and wear pad, offering many advantages.

Learn More

This patented new design SMART PAD® system for heavy duty applications. Pads can form as thick as ½” Mild Steel to any radius.

Learn More

This patented new design SMART PAD® system has a unique molded steel rod and interlocking wear pad. Can be used for up to 3/8” stainless steel.

Learn MoreListen to what our clients are saying about SMART PAD®

Custom Conveyor Corporation designs and builds material handling systems for the Municipal Waste Water market. This type of conveyor uses a U-Trough to house the screw or auger. The old process to make these troughs is to use the multiple 5° breaks to create the 180° bend in stainless steel. This method has several major issues:

- Each time the stainless steel comes in contact with the punch and the die, it imbeds mild steel into the sheet.

- Stainless steel reacts differently sheet to sheet and within a sheet to produce a distorted trough. The trough has to be manipulated to return to the desired shape.

- The process is operator dependent for quality and productivity.

We contacted Polyurethane Products Corp. for a solution to our manufacturing process. We described our needs and objectives and they had a solution. We provided test material and they developed the dies and radius punch. We traveled to Polyurethane Products for a demonstration of the process. In five minutes, we knew we had the answer to a production bottleneck.

The new process uses a variety of steel radial punches pressing into a polyurethane bottom die called SMART PAD®. The small size troughs now require only three strokes to accomplish what took 37 strokes before. The additional advantage is that our product now has a smooth rolled appearance, rather than the chatter marks of multiple breaks. This is a great help, as we bend stainless steel up to ¼” thick. Our productivity has us making the troughs in one-quarter of the time and our fit up is one hour less per trough because the troughs are perfect.

Using steel radius punches by Press Brake Tooling Corp. and the unique SMART PAD® by Polyurethane Products Corp., we were able to have a single-source solution for our radius products and greatly improved our productivity."

- Custom Conveyor Corporation

Watch the Process

Watch as the SMART PAD® tooling system is used to create a 4” radius 180 degree bend in 3 hits. Our customer was taking over 37 hits to create his 180 degree bends, without receiving consistent radii, and having multiple distorted bend lines throughout the piece. With the smart pad we were able to offer our customer smooth, mar-free bends with the ability to produce the parts in 1/16 of the time.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.