Amada Press Brake Tooling

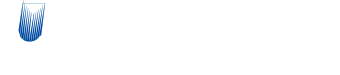

Create NO MAR designs with our molded Urethane V-Dies & Steel Holders and molded pads with

60mm x 18mm tangs, designed specifically for Amada press brake tooling.

All RETAINERS are made of steel.

AMADA V-Dies

- V-Dies are molded with a very hard grade Urethane with different v-openings for different gages for MAR-FREE bending of pre-polished, pre-painted & pre-finished metals in the punch press tooling process.

- These Pads are designed to be used in steel holders, with a special tang to mount directly on a AMADA Press Brake.

- Available for 90 Degree & Acute angle bends.

AMADA Quick Change 2V-Dies

- 2V-Dies are molded in a very hard grade Urethane with different v-openings for different gauges for MAR-FREE bending of pre-polished, pre-painted & pre-finished metals.

- These Pads are designed to be used with a special steel rail that will position the different V-opening to line up with the center line of the machine. Rail Part Number: PQCR2T

- Available for 90 Degree & Acute angle bends.

AMADA 4V-Dies

- 4V-Dies are molded in a very hard grade Urethane with different v-openings for different gages of sheet metal for MAR-FREE bending of pre-polished, pre-painted & pre-finished metals.

- These Pads are designed to be used in special steel holders, with a tang to mount directly on a AMADA Press Brake.

AMADA Urethane Pads

- Forming Pads for AMADA Style PRESS BRAKES are used in machined Steel Retainers.

- Used for MAR-FREE bending of Pre-polished, pre-painted and coated sheet metal.

- Pads are available in different deflections (hardnesses), color coded for bending different gauges of sheet metal.

- Square shaped pads offer 4 working surfaces, and rectangular pads offer 2 working surfaces.

- Some Pads have molded holes through the full length of Pads to reduce tonnage required, used for larger radius bending applications.

Urethane V-Pads

V-Pads are triangular shaped inserts designed for MAR-FREE bending and in applications where a very short leg is to be formed that is smaller than the v-opening of the die.

AMADA PODs For Radius V-Bends

- PODs are square or Rectangular shaped pads, with a flat top, designed for bending sharp or Radiused V-Bends.

- A molded hole through the full length of the pad provide for stress relief and require lower tonnage.

- PODs are designed to fit in standard ASTM Steel C-channels, to function as holders or Retainers

AMADA PUDs For Radius V-Bends

- PUDs are square or Rectangular shaped Pads with a molded U-shaped top surface to enable 180 degrees U-Bends in one hit.

- A molded hole through the full length of the pad provide for stress relief and require lower tonnage.

- PUDs are designed to fit in standard ASTM Steel C-channels, to function as holders or Retainers

Molded Tang Pads - AMADA/PODTs for Radius V-Bends

These Pads have a molded tang to fit AMADA style Press Brakes.

- Available in 48" lengths, with a flat top surface of 3" or 4" width

- Designed for sharp or radius V-bends and for bump-forming any radius with a punch width of 50% of the pad width penetrating the pad

- Punch length must be equal to or longer than the pad length so as to avoid the punch ends cutting

PUDTs for Radius U-Bends

These Pads have a molded U-shaped groove on top surface, for one hit U-forming of various outside radii.

- These Pads have a molded tang to fit AMADA style Press Brakes.

- Available in 48" lengths, with a flat top surface of 3" width.

- Punch length must be equal to or longer than the pad length so as to avoid the punch ends cutting into the pad.

PBNTs for Bull-Nose Bending

These Pads are designed for 2 hit-180 degree

BULL NOSE BENDING.

- During the first hit, a 100 degree arc is formed. Feeding the sheet metal in, and setting the back gauge so that there is a 10 degree overlap between the 2 bends, a perfect 180 degree bend is formed.

- The molded back stop enables bending very close to the edge of the sheet metal.

- The designated Radii in the pad are to be the outside radii on the part, allowing for spring back. The punch radius must be at least one metal thickness smaller than the pad radius.

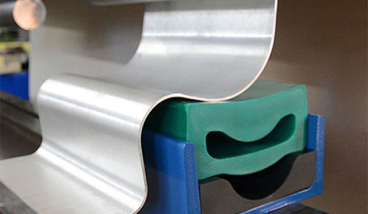

Large Radius Bending - SMART PADS

Hundreds of this original design SMART PAD® are in use all over the world for more than 3 decades.

Learn More

The original design SMART PAD® for smaller radius forming. This pad is ideal for radii ranging from 1”-3”.

Learn More

This patented new design SMART PAD® system is an improved design with interlocking forming pad and wear pad, offering many advantages.

Learn More

This patented new design SMART PAD® system for heavy duty applications. Pads can form as thick as ½” Mild Steel to any radius.

Learn More

This patented new design SMART PAD® system has a unique molded steel rod and interlocking wear pad. Can be used for up to 3/8” stainless steel.

Learn MoreThis Original design Radius Bending system has been a very successful tool used by Hundreds of Fabricating shops, for about 30 years.

- Designed for bending up to 1/4" thick Stainless Steel

- Pads are molded in 48" lengths, and for longer bends, pads can be butted together end to end to make any length.

- We have produced dies 65 ft. long to produce tapered light poles.

- Wear pads are used to reduce damage from sharp sheet metal blanks cutting into the forming pad.

You have questions, we have answers. Contact us today. Our skilled customer service specialists can help you make the right choice in polyurethane applications.